Automotive

Our constantly evolving range covers over 90% of the circulating car fleet

Product range

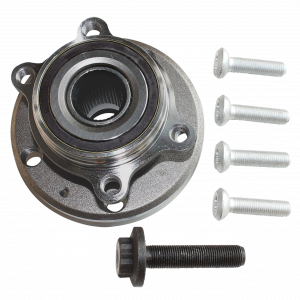

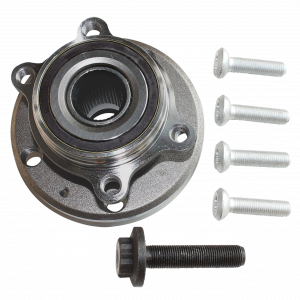

Wheel bearing kits

Wheel bearing kits are divided into first, second and third generation wheel bearings, complete with mounting accessories.

Automatic timing belt tensioners

Automatic belt tensioners are devices able to maintain proper timing belt tension, balancing any variation at all times.

Automatic auxiliary belt tensioners

Automatic auxiliary belt tensioners guarantee the proper belt tension by reducing noise and attenuating voltage peaks and slipping.

Timing belt tensioners

Timing belt tensioners adjust belt tension to the correct level.

Timing belt kits

In Motion offers a wide range of timing belt kits, covering over 90% of the circulating fleet.

Our quality tensioners and Dayco belts guarantee reliability and convenience.

Water pump kits

Our quality tensioners combined with Dayco belts and European water pumps guarantee reliability and convenience.

Overrunning alternator pulleys

They reduce the stress related to both engine cyclicity and sudden changes in rotation and torque.

These pulleys operate the alternator during the crankshaft acceleration phases and allow you to maintain and extend the service life of both belt alternator and the entire auxiliary system.

U-joints

Universal joints are the most important part of a gimbal and proportion is therefore the key feature for their correct operation and duration.

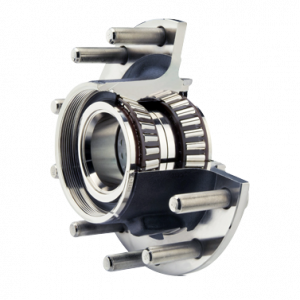

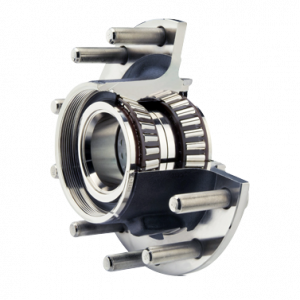

Wheel hubs

Wheel hubs are complex systems subjected to cyclic stresses and performing different functions. Quality and durability over time can only be guaranteed by the correct size and the choice of the most suitable materials.

In Motion supplies high-purity forged steel hubs.

Air conditioning bearings

Nowadays most of the vehicles are equipped with air conditioners.

Compressor manufacturers find Ima bearings suitable for their application.

Clutch release bearings

In Motion clutch-release bearings offer reliability and gear shifting fluidity.

Pulleys

Pulleys or idlers are used both in the engine timing system and in the auxiliary equipment.

Their aim is to ensure the correct winding angle on pulleys and belt tensioners as well as to check any belt vibration in case the span between the pulleys is too wide.

In Motion supplies a broad range of metal or plastic pulleys with single or double row ball bearings.

Production

Our production takes place on latest-generation lines.

High-technology production process and strict quality controls at our plants in Xinchang Zhejiang (China) and Lombardore (Italy) guarantee product reliability over time.

Quality

In Motion’s ongoing investment in production monitoring and special test benches ensures strict controls. They cover the whole process from incoming material analysis up to the finished product and packaging.

Reliability

From design to after-sales service, we are always by your side.

In Motion offers qualified technical assistance right from the beginning of the project, capillary sales network and a reliable service that reaches the final consumer.

Moreover, In Motion guarantees adequate stock levels in order to ensure rapid and timely delivery.