Automotive Production

Automotive Production

Product development

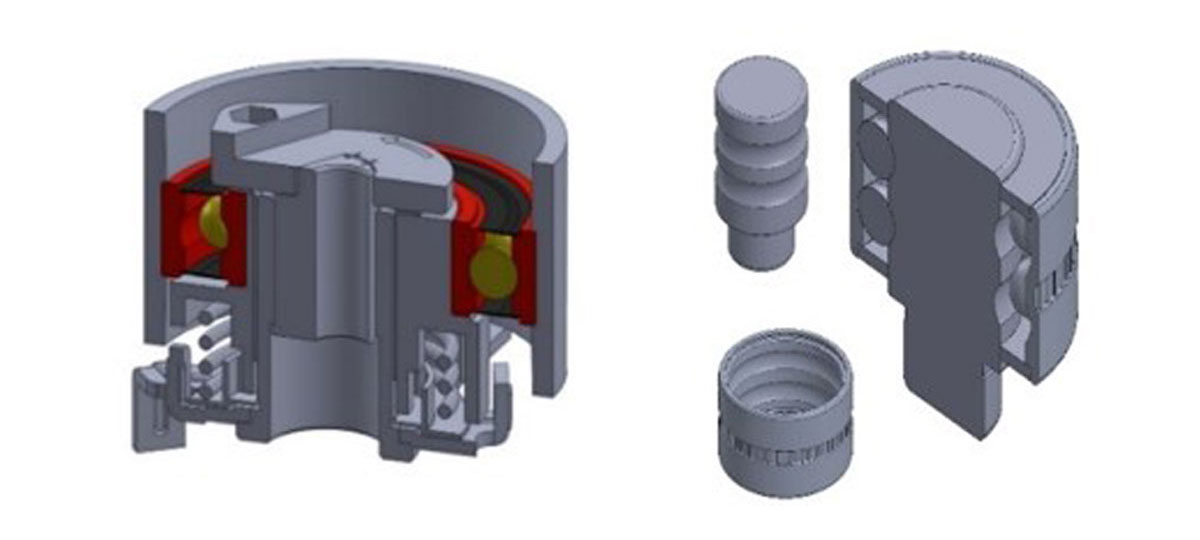

All products are developed internally starting from the customer's drawing or sample.

Life test

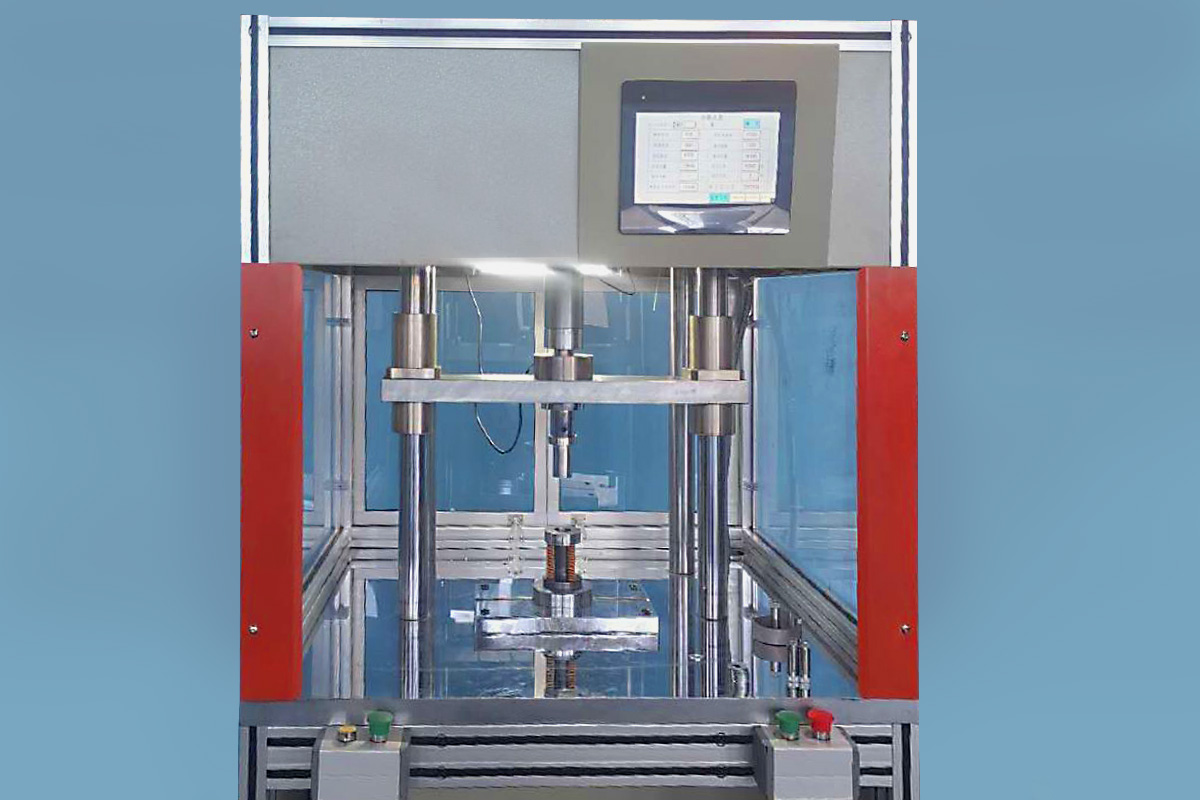

On design completion, prototyping and life test are carried out. Life test at controlled temperature, speed and loads allows us not only to validate the product in a relatively short time but also to identify areas for improvement.

Assembly

The assembly of both automatic auxiliary and timing belt tensioners takes place on semi-automatic lines equipped with servomotors designed to control Force and Displacement values.

This process guarantees the correct assembly of bearings as well as dampers, in some cases.

Once assembled, the belt tensioner is 100% checked on a semi-automatic bench able to measure torque and damping as well as pulley flatness.

As for the Italian plant, the production capacity per line is 300,000 automatic auxiliary belt tensioners and 350,000 automatic timing belt tensioners per year.

Industry 4.0

In accordance with the requirements of Industry 4.0, the plants are integrated with the company information systems through a dedicated MES. As a result, we are able to collect data in a timely manner and monitor the production output in terms of efficiency and quality.